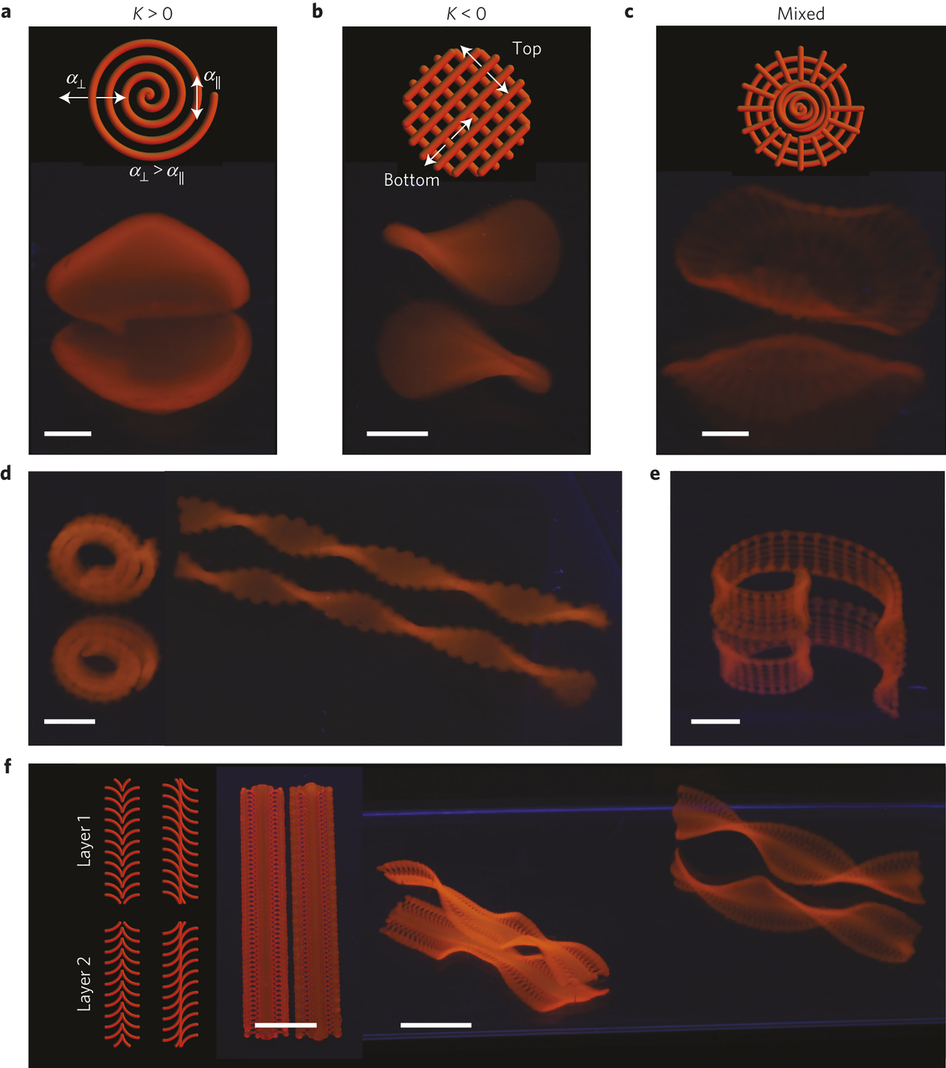

The 3D configuration of such materials changes upon activation, thereby altering their functions and properties (e.g., stiffness or wave propagation properties 12, 13). 3D-to-3D shape-shifting, on the other hand, is particularly useful for the fabrication of reconfigurable materials 10, 11. The main advantage lies in the ability to employ planar fabrication techniques for affording an ultimately 3D object with functionalities that originate from micro-/nanoscale surface features 7, 8, 9. 2D-to-3D shape-shifting enables flat constructs to fold themselves into geometrically complex 3D objects. There are two major categories of shape-shifting: 2D-to-3D and 3D-to-3D. Other examples are origami-based metamaterials 3, 4, 5 or self-folding bio-scaffolds made from (nano-)patterned 2D sheets 6. For example, a flat mechanism can shift its shape into a fully functional robot 1, 2. Shape-shifting empowers the development of designer materials with advanced functionalities and properties. We showcase the potential of the proposed approach for the fabrication of deployable medical devices including deployable bifurcation stents that are otherwise extremely challenging to create. We demonstrate how this modified printer can be combined with various design strategies to achieve high levels of complexity and versatility in the 3D-to-3D shape-shifting behavior of our reconfigurable materials and devices. This simple modification allows the printer to print on curved surfaces. Here, we present a single-step production method for the fabrication and programming of 3D-to-3D shape-changing materials, which requires nothing more than a simple modification of widely available fused deposition modeling (FDM) printers. That is caused by the intrinsically 2D nature of the layer-by-layer manner of fabrication, which limits the possible shape-shifting modes of 4D printed reconfigurable materials. As compared with the 4D printing of 2D-to-3D shape-shifting materials, the 4D printing of reconfigurable (i.e., 3D-to-3D shape-shifting) materials remains challenging. Upon activation, not only a change in their shape but also a large shift in their material properties can be realized. The partnership also allows the School to offer a truly world-class postgraduate research programme, which aims to attract some of the world’s best and brightest design students.Shape-shifting materials are a powerful tool for the fabrication of reconfigurable materials.

Sustainable printing-finding new ways to reuse plastic waste in 4D printing.Data printing-where big data is ‘infused’ into the printed object allowing it to adapt to changes in the environment.The 4D printing lab is part of the School of Design Innovation’s MADE research group, and is working in two main research areas: Imagine a 3D-printed flower that slowly blooms in the sun. It can produce transparent and flexible objects that are only achievable on Stratasys’ machines.ĤD printing takes static 3D forms and adds a new dimension-so the object can transform over time in response to stimuli such as heat or moisture. The partnership has meant the University has secured a new state of the art multi-material Stratasys printer. Catching the attention of the US-based company Stratasys, it is now working in a formal partnership that is enabling the creation of a new centre of innovation in Wellington. Over the past 15 years, the School of Design Innovation has carved out an international reputation for innovative research using 3D printing. A new 4D printing research laboratory is set up in a partnership between our School of Design Innovation and world-leader in 3D printing technology, Stratasys.

0 kommentar(er)

0 kommentar(er)